tedvisaya.info | Last update 01/08/2026 | © 2026 Teodoro Visaya

Teodoro "Ted" Visaya

Welcome to my World

Career Reflections

About Me

Aloha!

Welcome to my employment and academic journal. I’m a technical design specialist from California. I use creative and technical skills to solve tough design problems and develop new solutions.

I have extensive experience in research and development—especially product development, conceptual design, vendor fabrication, and manufacturing. With technical skills gained through work experience and education, I quickly understand engineering design situations and excel at finding practical solutions.

Over the years, I’ve worked across many industries: defense, semiconductor fabrication and equipment, medical devices, civil engineering, solar thermal, and high-end home renovations. I’ve contributed to equipment systems from robotics to process tools. I’ve helped design medical equipment, including body scanners, laser surgery systems, and biotech tools. At NASA Ames Research Center, I worked on space-flight equipment used in space shuttle missions. At companies such as Varian, Watkins-Johnson, and Teledyne, I worked on satellite communications and defense systems.

My main strengths include systems design, reverse engineering, new product integration, manufacturing, and sustaining engineering. I also have experience in civil infrastructure, mechanical HVAC, and piping and instrumentation diagrams (P&IDs).

I hope you enjoy reading this journal as much as I’ve enjoyed keeping a record of it. Mahalo Nui Loa for visiting, and please feel free to look around.

Silicon Valley

Silicon Valley:

An Established Culture

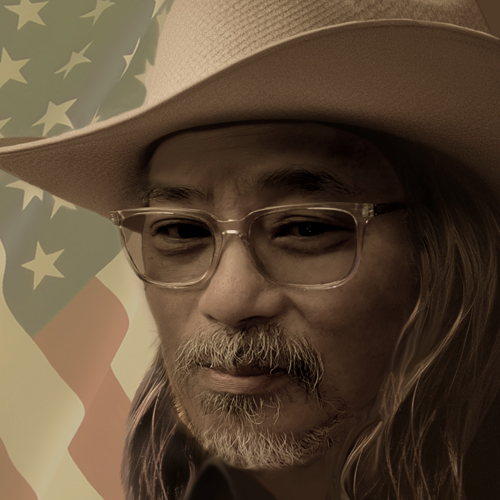

Silicon Valley stands apart because its ecosystem attracts brilliant minds from around the globe—and corporations follow that talent. Living in the Bay Area, you can feel the entrepreneurial spirit everywhere.

Local lore credits Stanford and early entrepreneurs—Hewlett and Packard, the Varian brothers, and others—for starting in garages and building world-changing companies. Palo Alto became famous for those garages. Nearby are theroots of Apple and Google, Facebook in Menlo Park, and Tesla across the bay in Fremont.

Silicon Valley is a global hub of high-tech innovation, and I’m grateful I got to be a part of it.

Post-Navy: The First Pivot Point

In the early 1980s, after I was honorably discharged from the U.S. Navy, I worked briefly as a jet mechanic in the civil service. Luckily, my brother Pete helped me get an entry-level draftsman job, even though I had no real experience—just a few drafting classes in high school. None-the-less, the company Teledyne CME was willing to give me a chance. They were a defense contractor desperate for drafters and designers.

That job was the pivot point. It helped me leave aircraft mechanics, which I hated, behind and move into work that suited me better: engineering drawing, technical publications, problem-solving, and eventually design engineering.

Cold War Context: Why Defense-Tech Was Everywhere

As a Cold War veteran, I saw up close how the U.S. standoff with Russia and China influenced everything—from politics to technology. In Silicon Valley, many companies focused heavily on national defense and homeland security.

One of the busiest areas was satellite communications, which accelerated under President Ronald Reagan’s Strategic Defense Initiative (“Star Wars”). Even though the full system was never built, the program poured billions into research and development, boosting major defense contractors and keeping smaller support companies busy as well. If you had any useful skills, finding a tech job back then was surprisingly easy.

Paradigm Shift: From Pencils to Pixels

Engineering design underwent a major transformation, moving from hand-drawn sketches to CAD. AutoCAD became the most widely used program. Some experienced designers didn’t want to switch and preferred their old methods—“you can’t teach an old dog new tricks.” They were comfortable with what they knew, but I was happy to use computers in my work.

At first, manual drafting could actually be faster because CAD had a learning curve. That created a divide: seasoned designers versus newer engineers who believed CAD would replace drafters and designers. Some people felt threatened—and I understood why.

But what became clear is that drafters and designers were often the best candidates to translate designs into clean, usable computerized drawings.

Drawing standards exist for one reason: clear engineering communication. A design drafter has to think like the person fabricating parts, troubleshooting systems, assembling equipment—and even the salesperson explaining the product’s nuances. You can’t assume anyone can “read your mind” from a drawing.

That’s why collaboration between engineering and design drafting became crucial.

INTRO: The Day Computers Walked In

When computers first showed up at work, most people treated them like a suspicious new coworker: “I’ll be polite, but I don’t trust you.” I was the opposite. I sat down, started clicking around, and thought, Oh… this is my kind of trouble.Going from hand drafting to CAD felt like upgrading from a bicycle to a small motorcycle—same balance, more speed, and a lot more ways to crash. I wasn’t an engineer. I was a drafter who liked drawing and didn’t mind learning machines, so I bought a computer for myself.

My first one was a humble little box: a PC 285-10 with an Intel 285 processor, a 10 MB hard drive, and 256 KB of RAM. Today, that sounds like nothing, but back then, it was enough power to run a serious operation—meaning it could boot up without smoking. I ran DOS 6 from a floppy disk, which also doubled as my entire backup plan.

Then came AutoCAD. I got an early copy through the ancient Silicon Valley tradition known as “a friend of a friend,” and I started drawing on the computer by pure persistence. No training, no manual—just trial-and-error and the occasional moment of panic when the screen did something unexpected and I thought I’d erased my future.

Silicon Valley: The Boom Years

Once I could draft on a computer, Silicon Valley didn’t see me as “just a drafter.” It saw me as useful—and in that era, useful meant employed.

I moved from job to job, but I usually landed on my feet because I had two things employers loved: CAD skills and experience around government contractors. The place was booming—DoD money was everywhere, Reagan was in office, and the Strategic Defense Initiative (“Star Wars”) had companies building everything from satellite communication components to countermeasure devices. If it sounded high-tech and expensive, somebody in a suit and tie was getting funded to make it.

Résumés: Where Drafting Turned Into Storytelling

That boom taught me something else: your skills don’t matter if you can’t explain them.

Having my own computer at home gave me an edge, especially with résumés. I used MS Word—my first word processor—and wrote my résumé like it was a product brochure. Some

engineering friends shared their résumés with me, and I followed their style.

engineering friends shared their résumés with me, and I followed their style.

That was the key. Once my résumé looked like an engineer’s résumé, employers started reading it like I was an engineer.

Did I lie? Not exactly. I didn’t invent projects. I just learned how to describe what I did in a way that sounded… impressively complicated. Let’s call it “enthusiastic interpretation.” It worked great at first: I’d get hired, walk in, do solid drafting work, and keep learning.

Eventually, the truth would show up like an unpaid bill: sooner or later, my real level of engineering knowledge would become obvious, and I’d get laid off—sometimes with a not so friendly helpful lecture included at no extra charge.

I fooled them all. I wasn't an engineer, I was an artist. Maybe a little bit of a con-artist, hahaha. Still, I kept going. And without realizing it, I was becoming something I didn’t expect: a good writer and storyteller.

Why This Journal Exists

Before I ever thought of myself as a writer, I was documenting my working life—job by job, role by role—learning to tell my own story through résumés.

This employment biography covers my work experience and responsibilities over the past 40 years. I’ve been updating it since 1982, which is when I started writing résumés and realized I actually enjoyed it. That was the start of my writing journey.

I took English writing classes in college to improve my skills and discovered I truly liked the craft. Who would’ve thought résumés would help me find my voice on paper?

How I Got Started (Temp Life + Hustle)

When I started in tech, I didn’t follow the usual job-application path. I got my start through temp jobs and staffing agencies, which was common for people like me who didn’t have a degree yet and were taking night classes.

I used to joke that temp workers were employment whores who couldn’t commit, and recruiters were employment pimp matchmakers. Even so, I kept hustling—always searching for the next job opportunity so I could stay employed and keep my skills sharp.

The Internet Arrives (and Everything Speeds Up)

From what I remember—and later confirmed—the Internet’s roots trace back to early DoD research networks like ARPANET. Over time, standards like TCP/IP helped networks expand, and efforts like NSFNET extended access to universities and research institutions.

By the early 1990s, the stage was set for commercial use. That opened the door to the Dot-Com Boom of the mid-to-late 1990s. It felt like it began with inter-office email and dial-up modems connecting home and work—then suddenly it took off. AOL and Netscape arrived, early web browsing became real, retailers moved online, and the world changed fast.

After the Cold War: When Jobs Got Competitive

The Cold War ended around 1991, right as the Dot-Com era was starting to grow. But peace also meant budget cuts. Defense contracts disappeared, companies shrank, and suddenly finding a job wasn’t so easy.

The industry became competitive quickly, and staying employed meant adapting fast—and often.

Skills

Skills + Gratitude

Skills + Gratitude

I’m incredibly thankful for the chance to acquire and develop advanced skills over four decades of work. As technology advanced, my computer competency evolved with it, and I gained confidence applying these skills in demanding environments.

Because of those computer skills, I had the opportunity to work across industries, including military defense, semiconductor fabrication, medical devices, civil engineering, solar thermal, and construction. In every setting, strong computer skills helped me adapt quickly and meet the company's standards.

Although I’ve experienced stress, anxiety, depression, humility—and more than a few hard lessons—I’m grateful for the chance to learn, grow, and collect valuable lifetime experiences.

“The true measure of wealth lies in the knowledge we accumulate—a priceless asset that can never be taken from us.”

UX Design & Research:

UX Design & Research:

- Qualitative & Quantitative Analytics

- Balsamiq - Wireframes app

- Axure RP - UX prototype building app

- Codepen - Front End development, HTML5, CSS3, Javascript

- Adobe Dreamweaver , Web Design, HTML,CSS, Javascript

Technical Publications:

- Adobe Photoshop & Illustrator

- Digital Graphic Illustrations

- Animated Gifs

- Artwork, Labels, Clip art

- Technical Writing for Manuals

- Marketing Literature

- Product Specification Sheets

- Technical Publications

- Document Control Management

- Enterprise Resource Planning (ERP)

- Inventory Database Management

CAD-Engineering:

Solidworks - CAD program

Solidworks - CAD program- Autodesk AutoCAD - CAD program

- Autodesk Inventor Professional - CAD program

- ProEngineer (earlier version 2000i) - CAD program

- CAD - 3D Printed Prototype Development

- Mechanical Conceptual Layout

- Mechanical Design Retrofits

- Mechanical Design for Vendor Fabrication

- Mechanical Assembly & BOMs (Bill of Materials)

- Electrical Schematics and interconnect Diagrams

- Electrical PCB Design and list of components

- Electrical Harness Assembly Fabrication and Tooling Setup.

CAD-Architectural:

- CAD - Chief Architect , residential floor plans and renovations

- CAD - Autocad

- Site Planning, Capital Equipment Placement

- Infrastructure BIM: Building Information Management

- Infrastructure P&ID: Piping & Instrumentation Diagrams for Building Sites

- Infrastructure Vendor Instrumentation Research-Development, and Design Implementation

- Infrastructure Piping Drawings for Building Sites and Roadways

- Infrastructure Structural Construction drawings

- Infrastructure HVAC: Heating, Venting, & Air Conditioning Drawings for Building Sites

- Infrastructure Electrical Conduit Schematic Diagrams / Drawings for Building Sites and Roadways

Employment History

Reflecting on my time as a contractor, I recall the stress, office politics, and discrimination that often accompanied the job. Still, there were also good moments. I made great friends and learned lessons that have stayed with me throughout my career. That knowledge is priceless, just as a good education is.

Early in my career, I used to worry a lot about layoffs. But as I learned more and built up my skills, I felt more confident and less afraid of losing my job. I started to see layoffs as a chance to rest or even take a vacation. I knew I would need to find work again, but I only started looking when I really needed the income.

Later in my career, I dealt with age discrimination. Companies often choose younger, less experienced workers because they cost less than someone with my background. That was tough to accept. But from a business perspective, it makes sense to hire people who are up to date with the latest technology. If I were in their place, I might do the same. I realized that as you get older, you may not be as valuable to the company. To stay useful, it's important to help younger employees adjust to the workplace. Think of it as giving back to the advancement of technology and the collective good of the industry.

Keeping up with new technology can be tough, especially as you get older. Still, your experience and skills are valuable in any field. Try to see each new project as a chance to learn something new. As a contractor, you can help out wherever you're needed and keep things moving forward. When you work on projects like medical devices or renewable energy, you can feel proud knowing you're making a real difference. Every project is a step toward your next opportunity, so stay positive and look forward to what's ahead.

SUMMARY OF EXPERIENCE:

1981 to 1982Naval Air Rework Facility (NARF), Naval Air Station Alameda, CA

Aircraft Power plant Mechanic

So, the day after I left the Navy with honor, I got a job as a temp worker for the civil service. I was working at the Depot level, where I was responsible for breaking down and rebuilding aircraft engines for the US Navy. I worked there for only one year and didn't seek permanent employment. I didn't want to be a grease monkey.

1982 to 1988

Teledyne CME, San Jose, CA (Autocad & Manual drawing by hand) Drafter

As a part of the Military Defense project, I provided extensive drafting and design support for developing

Airborne and Ship launched countermeasure equipment.

The project required extraordinary attention to detail, as the equipment had to be meticulously designed to ensure maximum effectiveness while being lightweight and easy to operate. My role included collaborating with engineers and project managers to develop technical drawings and blueprints and providing input on materials selection and manufacturing methods. Throughout the project, I worked closely with the team to ensure that all designs complied with government regulations and standards and that the equipment was thoroughly tested and validated before deployment.

- I designed potting molds for high-voltage RTV units.

- I made contributions to new product development and electronic packaging.

- I have manually generated small PCB design support of analog and digital multi-layer board assemblies using tracing tape on a mylar sheet.

1988 to 1989

WATKINS JOHNSON & VARIAN, Palo Alto, CA (Autocad & Manual drawing)

Contractor - Designer/Drafter

I was on assignment assisting a Joint Military Defense project between Watkins Johnson and Varian. Provided drafting and design support for Satellite Communications systems and provided design and standard drafting support for Signal Gun assemblies, TWT assemblies, and related power sources Satellite systems.

- Manual PCB design support of multi-layer power supply board assemblies.

- Made vital contributions to new product design by supplying drafting layouts, contributing to the R&D of new technology, and working with vendors and suppliers.

1989 to 1991

LOCKHEED LIFE SCIENCES @ NASA Ames Res Ctr, Moffet Field CA (Autocad)

Contractor - Designer/Drafter

I provided drafting and design support for an experimental space flight project that catered to the requirements of various customer countries such as Japan, Germany, and the United States. My work involved providing design and drafting support for space flight project requirements, ensuring compliance with the respective customer country standards.

- I contributed significantly to the new product development of equipment focused on scientific experimental projects. My role involved designing fixtures, rack and panel assembly modifications, power supplies, control units, cooling systems, UPS, and related cable harness assemblies. Additionally, I was responsible for developing transport design support in rodent cage carriers, equipment shipping containers,and specialized ground support equipment and adapters.

- I also generated periodic updates of the department design drafting manuals and procedures, ensuring full integration with DoD-STD-100/1000 drawing requirements and ANSI Y14.5 standards.

1991 to 1992

Loral Fairchild, Milpitas Ca (Autocad)

Contractor - Designer/Drafter

This division of Loral Fairchild's specializes in producing cutting-edge infrared camera surveillance systems. The systems are designed to serve in the security of both commercial and military defense sectors equally proficiently.

- I played a substantial role in developing infrared camera surveillance systems designed for commercial and military defense applications. My responsibilities included providing meticulous design and drafting support for existing infrared camera surveillance systems and industrial camera optics systems.

- I applied my expertise to contribute to the design of various components, such as enclosures and brackets, machined parts, cable harness assemblies, and the overall assembly production release. My focus on precision and attention to detail helped ensure that the final products were of the highest quality and capable of meeting the most demanding performance standards.

1992 to 1998

SCHLUMBERGER TECHNOLOGIES, Sunnyvale, CA (Pro-Engineer 2000i & Autocad)

Designer/Drafter – Technical Specialist

As a developer of integrated diagnostic and tester systems for the semiconductor industry, I provided drafting and design support for new product development of integrated diagnostic systems utilizing e-beam technology. My primary responsibilities included completing conceptual design layouts and standard drafting support for innovative diagnostic systems assemblies and tester equipment for back-end semiconductor development.

- I made vital contributions to new product integration upgrades by supplying design layouts, contributing to the R&D of new technology, and interfacing and working with vendors and suppliers. Additionally, I supported the design of calibration tools for systems using laser opto-mechanics for measurement diagnostics on a high-precision air suspension test bench.

- As part of my responsibilities, I was responsible for the materials evaluation and selection of 316 and aluminum alloy 6061 for machined parts and frame weldments, 1100 series, and 5052 aluminum for sheet metal panels, brackets, and enclosures. I also evaluated various polymers for non-conductive parts and tooling fixtures. Overall, my contributions were vital to the success of the integrated diagnostic and tester systems for the semiconductor industry.

1998 to 2001

GENUS TECHNOLOGIES, Sunnyvale, CA (Pro-Engineer 2000i)

Mechanical CAD Designer

Genus Technologies is a company that specializes in the development of Chemical Vapor Deposition (CVD) and Atomic Layer Deposition (ALD) systems for the semiconductor industry. As a hired contractor, I supported the core business by collaborating with colleagues to design CVD and ALD capital equipment. As part of my responsibilities, I utilized my expertise in design drafting to create conceptual layouts based on engineering design reviews and facilitated engineering changes and upgrades to existing systems.

Through my contributions, I assisted the engineering team in improving the quality assurance and efficiency of the equipment, which ultimately led to more tremendous operational success for the company.

- Made key contribution to new product integration upgrades by supplying design layouts, contributing research and development of new technology,mixed gas chambers and gas manifold assemblies. and interfacing and working with vendors and suppliers.

- Providing design layouts for engineering (NPI) New Product Integration reviews.

- Engaging in comprehensive exploration and experimentation to innovate novel technologies through diligent research and development processes and collaborating with vendors and suppliers.

2001 to 2003

GE MEDICAL SYSTEMS, San Francisco, CA (CoCreate Solid Designer, Solidworks, Autocad)

Mechanical CAD Designer

The company was a prominent developer of full body scanners, x-ray imaging, medical diagnostic, and biopharmaceutical technologies, now known as GE Healthcare. During my tenure, I took the initiative to revamp the engineering design review process by creating conceptual layouts and providing drafting support to facilitate engineering.

- Drafting documentation was created in CoCreate Solid Designer / engineering analysis documentation-FEA was created in Solidworks Cosmos. Used Autocad on occasion for facilities layouts, assembly and test instructions .

- I played a significant role in conceptualizing the design layouts for an oil-free system electron beam assembly. Additionally, I facilitated a substantial upgrade to an existing system by creating conceptual layouts. I also completed machine drawings for the electron beam assembly retrofit to ensure the project's success.

- The drafting documentation I created was developed using CoCreate Solid Designer, while the engineering analysis documentation was prepared using Solidworks Cosmos. In addition, Autocad was occasionally employed to prepare facility layouts, assembly, and test instructions, as necessary.

2003 to 2006

I took the time off to spend quality time with my mother, who was diagnosed with cancer.

2006 to 2008

2006 to 2008

ACCURAY INCORPORATED, Sunnyvale, CA (Solidworks 2008 & Autocad)

Mechanical CAD Designer ECO Processor

Manufacturer of ground-breaking radio surgery medical technologies. Contributed to ongoing refinement of company’s robotic radio surgery product by writing and incorporating engineering change orders (ECOs) for new product integration of precision patient-positioning system. Created assembly and fabrication drawings for next system upgrade improvements.

- Collaborated with colleagues in Physics Department to create conceptual layouts and completed design for laser image-calibration tool projects.

- Facilitated engineering upgrades to existing systems by integrating new designs for mounting support retrofits for electronic control system devices.

- SITE PLANNING: With new customer orders the Site Planning team would prepare plans to integrate new system installments at the customer site. It was my responsibility research customer facility sites for existing floor plans and create new drawings with integrated new system installation. I developed conceptual layouts for engineering review and equipment placement floor plans, elevation, plumbing, and electrical drawings.

2008 to 2009

APPLIED MATERIALS, Fairfield, CA (Solidworks 2008 & Autocad 2008)

Contract Mechanical Cad Designer

Developer of large-scale industrial glass-coating equipment. Supported core business by collaborating with colleagues in design of capital equipment. Created conceptual layouts from engineering design reviews. Facilitated engineering changes and upgrades to existing systems by providing design drafting expertise.

- Completed conceptual design layouts for retrofit upgrade to an existing industrial glass coating assembly.

- Made key contribution to critical system upgrade by supplying design drawings and technical publications support.

- Responsible for materials evaluations and selection SST 304 & 316 and aluminum alloy 6061 for machined parts 1100 series and 5052 aluminum for sheet metal panels, brackets, and enclosures.

- Collaborated with mechanical engineer for FEA evaluations on stress and thermal expansion on modeled parts. Incorporated mass properties and ran calculations on Solidworks Cosmos program.

2011 to 2012

RF BIOCIDICS, Vacaville CA (Autodesk Inventor Professional 2012 & Autocad 2012)

Senior Designer, As an integral member of a dynamic design team, I actively developed advanced RF and Microwave systems for disinfecting and disinfesting food products. My responsibilities primarily involved working with my colleagues to ideate, design, and test cutting-edge technologies to ensure food products' safety, quality, and nutritional value. Our team's collective efforts created highly efficient and effective systems that have revolutionized the food industry's food safety and hygiene approach. The impact of our work has been significant, and the systems we developed have significantly contributed to the enhancement of food safety standards and practices in the industry.

- The scope of my responsibilities involved creating conceptual design layouts for the fabrication of total system cabinets and developing comprehensive engineering documentation to release the product for manufacturing.

- One of my primary responsibilities involves evaluating and selecting materials for various applications. In this regard, I predominantly employ aluminum alloy 6061 for tubing and machined parts, while for sheet metal panels and enclosures, I prefer 1100 and 5052 alloys. For continuously moving parts, I opt for 304 and 316 alloys. Additionally, I commonly utilize polymers such as Delrin, ABS, and Teflon for non-conductive parts and tooling fixtures. These materials are selected based on their unique properties and characteristics, which are carefully assessed to ensure that they meet the requirements of the intended application. By employing a rigorous selection process, I can deliver high-quality, reliable products that meet the needs of our clients.

- While collaborating with a mechanical systems engineer, I assisted in incorporating mass properties and running stress evaluations for modeled parts using Autodesk Inventor's FEA simulations.

CAD Contractor:

- 8-2013 to 1-2014

R&D Technical @ Therma Flite, Benicia CA

Hired on contract to work closely with the engineering team to ensure that all drawings meet the required standards and specifications and are completed within the given timelines. My role also involves evaluating changes in any technical issues that may arise during the drawing process and providing necessary support to the team to ensure that all their requirements are met. - 2-2014 to 9-2014

On Disability: Went under the knife for corrective back surgery. I did not fully recover to normal, but I was able to work with restrictions. I was placed on permanent disability, approved by the State of California.

My surgery was caused by years of slouching behind a desk without proper posture. The cartilage between the three lower disks of my spine thinned until the disks were bone on bone.

If you sit at a computer all day, take this as a warning: stand up and walk around every 30 minutes. This is common practice in Japan for good reason. Try working while standing. Ask for an adjustable desk or a standing workstation. It can make a big difference. - 9-2014 to 11-2014

Planet Pharma Staffing Agency @ Biomarin, Novato CA

During a short-term engagement, I had the opportunity to assist the facilities department at BioMarin located in Novato with streamlining their backlog of Piping and Instrumentation Diagram (P&ID) drawings. As a part of my role, I provided drafting support to the teams responsible for ensuring new equipment placements and complying with the environmental safety requirements. This experience allowed me to leverage my expertise and play a vital role in helping the company achieve its goals. - 1-2015 to 2-2015

Versa Engineering, Concord CA

Temporary 1099 contract work. I was recently hired for another short-term contract to help clean up and finalize a project that involved upgrading an oil refinery. As part of the engineering team, my primary responsibility was to update the Piping and Instrumentation Diagrams (P&IDs) in accordance with the current upgrades and source control guidelines. These diagrams are critical engineering documents that provide a detailed illustration of a process plant's piping, equipment, and instrumentation. My updates ensured that the P&IDs accurately reflected the desired plant configuration while ensuring the safety and efficiency of the production process. - 2-2015 to 6-2015

Sanovas, San Rafael CA

In my previous employment, I provided comprehensive visual graphic design support to multiple departments within the organization. I was the go-to person for creating and producing product literature and conceptual marketing artwork in the marketing department. I also supported the Compliance and Regulatory department by generating Product labels and operating instructions aligned with the company's standards.

I had the opportunity to collaborate with the CEO and the engineering team in developing CAD drawings and documentation, respectively, and creating Visual Artwork for patent submissions. I was instrumental in ensuring that the drawings and technical publications were stored in a well-maintained and up-to-date CAD Vault database, facilitating easy access and retrieval of information by team members. - 8-2015 to 9-2015

Cost Plus World Market Corporate HQ, Oakland CA

I was employed for a brief contract assignment with the Visual Merchandising team. My responsibility was implementing Home Relay interior store upgrades in 79 selected stores nationwide. Additionally, I utilized AutoCAD to create analytical design solutions for integrating new fixture displays within existing store floor plans.

This was a one-month contract, and I was eager to finish it and move on to another assignment.

The company could have been an ideal work environment for me. I felt uncomfortable there and believed my professional design experience wasn't being utilized to its full potential. In other words, I wasn't learning anything worthwhile. - 9-2015 to 3-2016

Kiewit Infrastructure West Co. – Fairfield CA

During my contract assignment, I had the opportunity to provide drafting support for the HTWTP, Harry Tracy Water Treatment Plant, which is owned by the San Francisco Public Utilities Commission (PUC). I updated over 100 drawings to an as-built condition for six months, incorporating all minor and significant changes. My tasks included design-drafting support for seismic study improvement upgrades, structural retrofits, HVAC mechanical retrofits, piping plans, lighting schematics, electrical schematics, instrumentation diagrams, and P&ID updates. My contract objective was to complete all loose ends of the projects and deliver them in a fully finished condition.

Working at Kiewit was a valuable experience for me, as I gained a lot of knowledge about civil engineering, the San Francisco Harry Tracy Water Treatment Plant, and why San Francisco is renowned for having the best water in the nation.

Mar 2016 – Oct 2017

Heliodyne Inc. (Solidworks, Autocad, Photoshop, Illustrator, InDesign, Dreamweaver)

Engineering Design Documentation Specialist

Location: Richmond California

During my previous employment, I was tasked with managing various responsibilities that pertained to subsystems. I was responsible for overseeing and coordinating activities related to these subsystems. Additionally, I contributed to developing and designing precise system weldment frames, sheet metal panels, brackets, and electronic control system assemblies. I also created plumbing and piping diagrams and assemblies, utilizing Solidworks CAD to design the assemblies. I prepared design documentation such as drawings, models, specifications, and production release documents as part of my duties. I created, approved, revised, and maintained design documentation and developed and suggested alternative design approaches whenever necessary.

Furthermore, I identified innovative product development solutions and developed, quoted, and executed plans to meet technical requirements and requests. I also assisted in the vendor selection/evaluation process. In addition, I supported the sales department with technical publications and data specification information and independently maintained installation and service manuals.

As part of my role, I engaged Adobe Illustrator, Photoshop, and InDesign to design wiring diagrams, labels, spec sheets, and manuals. Lastly, I created, updated, and maintained BOMs, new parts, assemblies, and sub-assemblies using the FishBowl database program.

Dec 2017 - APR 2018

DRB Homes

CAD Artist, architectural-residential designer

Location: Alamo California

As an integral member of a collaborative team, I played a pivotal role in the design and execution of high-end residential renovations. My proficiency in CAD software, such as Chief Architect, proved instrumental in creating meticulous renderings, floor plans, and drawings that not only met but exceeded our clients' expectations. Working closely with the team from conceptualization to completion, I ensured that every aspect of the project was executed to perfection, resulting in visually stunning, functional, and captivating living spaces.

APR 2018 - July 2019

Freelance Digital Designer

Vallejo California

As a designer, I've been fortunate enough to work on various exciting projects throughout my career. From creating stunning Medical Artwork, Animated Gifs, Event Flyers, Logos, Clip Art, to tackling home renovations, I've been able to showcase my creativity and passion for design.

As a designer, I've been fortunate enough to work on various exciting projects throughout my career. From creating stunning Medical Artwork, Animated Gifs, Event Flyers, Logos, Clip Art, to tackling home renovations, I've been able to showcase my creativity and passion for design.

However, since January 2020, things have been quiet on the job front. I suspect this is due to the ongoing COVID-19 pandemic, which has affected many industries and businesses worldwide.

On the bright side, my experience designing for biotech pharmaceutical companies has given me a unique skill set. I'm well-versed in creating product handling labels that meet industry regulations and comply with FDA and GMP standards. Additionally, I've designed packing and shipping labels that conform to the international requirements of various foreign countries.

At manufacturing companies, I've had the opportunity to tackle a wide range of design challenges. I've learned and grown as a designer, from crafting artwork for product serial number nameplates to designing safety handling, hazardous materials, and product labels that guide proper operational application.

July 2019 to 2022 Honolulu Bohemian LLC

I pursued my passion for digital arts as an artist-designer and continued my research in behavioral graphic communications by relocating to the Honolulu Arts District, Chinatown. The Board of Directors, led by Kim Taylor Reese, granted me an art studio lease at the Chinatown Artists Lofts, which the Hawaiian Arts and Performing Arts Committee approved for participation in the Mark's Garage art exhibitions and the First Friday Events on Hotel Street. However, the ongoing COVID-19 pandemic has caused economic setbacks that have hindered productivity. Only now, in the summer of 2021, productivity is beginning to pick up again.

July 2022-Present, Writer - Author

I delved into the rich and captivating history of Honolulu's Chinatown Arts District, immersing myself in the vibrant and dynamic culture of the area. Driven by my love for writing, I channeled my passion into crafting my first fiction novel, "Hotel Street." Through my writing, I sought to capture the essence and spirit of this unique and fascinating locale, weaving together a tale that brings to life the sights, sounds, and characters of this vibrant community.

Hotel Street.

Hotel Street was the red light district and central hub of all activities in Honolulu during the late 1800s and early 1900s. The transfer of power from the Monarchy to the Provisional Government was marred by widespread corruption, leading to a chaotic atmosphere that resembled the lawless Wild West. The recent passage of the McKinley Tariff increased export taxes for Hawaii, which had previously enjoyed duty-free trade with the US.

Plantation owners wanted to annex Hawaii to save the economy and eliminate the McKinley Tariff taxes. However, this resulted in the dissolution of the Hawaiian Monarchy. King Kalakaua's health was affected by these events, and he secretly sought support from allies in California.

The journey of writing has its unique twists and turns. It takes courage to revisit the works we've created and make them better. That's precisely what I did when I finished writing "Hotel Street."

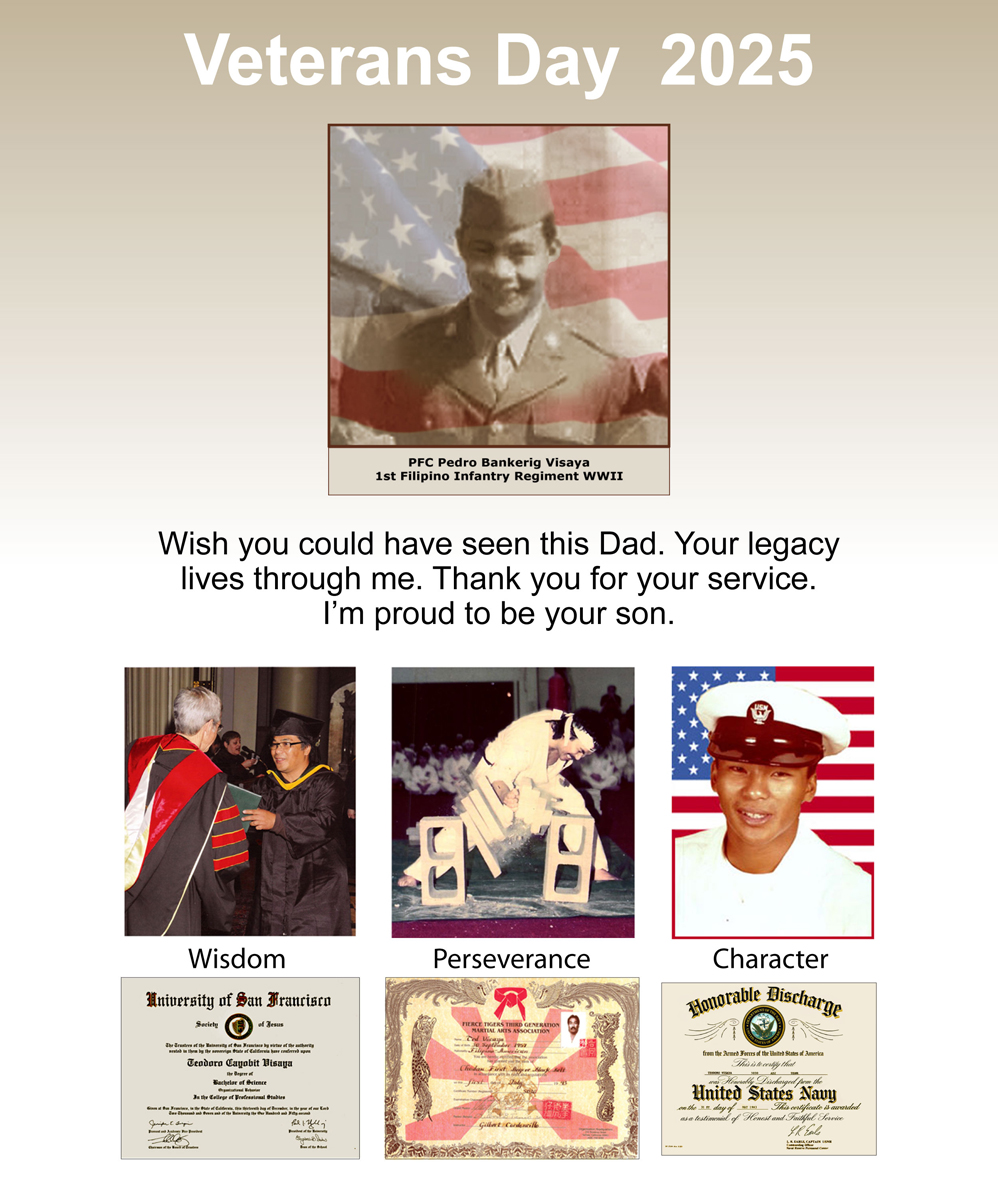

I returned and reviewed my first book, "Tales from Dad's Toolshed and Mom's Footlocker." It was a collection of stories I wrote for my kids, and it followed my father's journey from immigrating to Hawaii to work in the sugar plantations to moving to California as a farmworker. The stories reflected my father's indomitable spirit and resilience in adversity.

With a renewed sense of purpose, I re-wrote all the stories, added more graphics, and used AI technology to craft some new ones. The result was a book that I named "A Fil-Am Journey." My story picks up where my parents left off when our family settled in the Silicon Valley area. It's a testament to the power of perseverance and the human spirit to overcome obstacles and create a legacy that inspires future generations.

Academics

I like to joke that I spent 30 years in junior college—but honestly, I’ve just never been able to quit learning.

Even after leaving the U.S. Navy, I kept taking classes and hunting down courses online. I worked full-time during the day, so evenings were my only option… which is exactly where that “junior college forever” joke comes from. These days, I’m online a lot, and I treat it like a giant all-you-can-learn buffet. If there’s a chance to sharpen my computer skills, read something useful, or watch an educational video, I’m in. I try to see every day as a small upgrade—one new thing at a time.

And here’s the real payoff: learning keeps your brain awake. It’s mental mileage. It helps you stay sharp, keeps the cobwebs off, helps prevent dementia, and makes you feel a little more “young” on the inside—even when your body mechanics might respectfully disagree. I’m not aiming to be Einstein. I’m aiming to keep growing until the very end. And I’m proud of what I’ve picked up over the years—skills, knowledge, and the confidence that comes from proving to yourself you can still learn new tricks.

That’s the part I want to pass on: keep chasing knowledge. Stay curious. Don’t let your last “first day” of learning sneak up on you. I’m still stalking classes online, and taking classes at local colleges and universities whenever I can—and I plan to keep going.

EDUCATION:

1991-92 / 94-96 Mission College, Santa Clara California Mission College (part-time while working full-time)

General Education lower division transfer units, Mechanical Drafting, Printed Circuit Design, English writing and Communications, Public Speaking and debate.

1997-98 / 2006-2007

University of San Francisco USF

2130 Fulton St, San Francisco, CA

Bachelor of Science, Organizational Behavior from the

College of Professional Studies, received undergraduate degree in 2007.

- The course of study in Organizational Behavior at the college of professional studies program at USF was centered around researching and analyzing organizational dynamics and behavioral science. Taking a critical approach to understanding corporate business culture(s) and structure(s), and how and why they operate.

- Acquired skills in qualitative and quantitative methods of research, organizational assessment, diagnostic-analytics, implementation, evaluation, and design to assume leadership roles in organizational departmental development and management. Ideal for positions in program management as a director.

2009-2010 SFSU Computer Traning Center San Francisco downtown off campus center, 2009 – 2010

- Vocational skills training, Multimedia - WEB Design & Development Vocational job retraining program sponsored by the Workforce Investment Board of Solano County. Funding for this program came from Federal Government stimulus money under President Obama for unemployement and new vocational training.

2024 University of Hawai'i Manoa Spring & sessions

OLLI, Osher Liifelong Learning Institute,

Local Hawaiian Short Story class

2023 University of Hawai'i Manoa Spring & Fall sessions

OLLI, Osher Liifelong Learning Institute,

Book writiing, Short Story writiing, ,Llfe writing classes

U.S. Navy Military Service

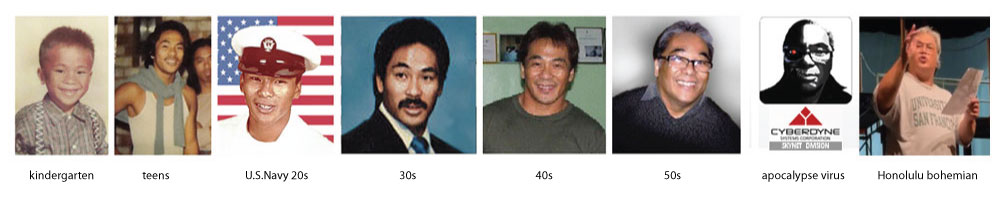

In my turbulent teenage days, I got into a lot of trouble. I was constantly drinking or getting high on marijuana. I was going nowhere fast, so I had to change and escape this losing lifestyle. After being stuck with dishwasher and warehouse jobs due to lacking skills, I found my way out through military service.

Initially, my main objective wasn't patriotism. I aimed to acquire a skill that would enable me to secure a decent job. Fortunately, I was assigned to the Naval Air Station Alameda, AIMD (Aviation Intermediate Maintenance Division), which was so close to my home, just by requesting it. I enlisted in the Navy as an Aviation Machinist Mate (Jet Engine Mechanic) to learn a skill. I put in a lot of effort and dedication, and it paid off as I rose to the E5-2nd Class Petty Officer rank in just three years. Despite excelling in my exams and studies, I struggled as a mechanic and I sucked big time at it.

Through my military experience, I learned the importance of teamwork. All of us needed to collaborate to succeed. Being in that environment, I gained a sense of gratitude, trust in my fellow sailors, and a strong sense of pride in being a part of a team and the American military. The military served as a second father figure and helped set me on the right path. If given the opportunity, I would embark on a military career and go to sea onceagain. Although I have considered returning, I am humbled and honored to have served and proud to be a veteran.

MILITARY SERVICE:

1977 - 1981 Active Service / 82-83 ReservesU.S.Navy Veteran - Honorable Discharge Aviation Machinist Mate, PO2-ADJ (E5) Petty Officer 2nd Class (E5) Aviation Machinist Mate specializing in intermediate maintenance of jet aircraft engines and helicopter power plants. Last attached to AIMD and the HS-85 Antisubmarine Warfare Reconnaissance Squadron.

- I entered into the Navy as a jet mechanic and received basic aviation fundamentals training at NAS Millington training command, Tennessee.

- Reassigned to NAS North Island CA for addition helicopter power plants and flight deck training. Specialized training on the GE T58 power plant for Sikorsky helicopters SH60 Navy helicopters and H3 Marine helicopters.

- Reassigned to NAS Alameda AIMD in support of the HS85 Anti-Submarine warfare reconnaissance squadron.

- Received addition training on the T56-A-10 for the P3 Orion military aircraft.